PRODUCT CENTER

We not only enjoy high reputation in the domestic market, but also open the door of overseas market since 2008 when we set up the Foreign Trade Department. Products have been exported to Asia, North America, South America, Australia, New Zealand and other countries and regions.

Product Categories

Categories:

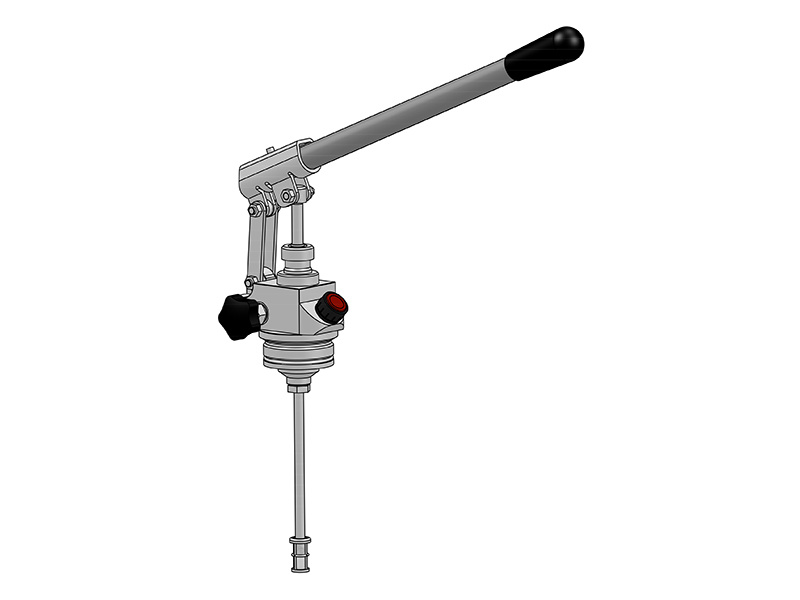

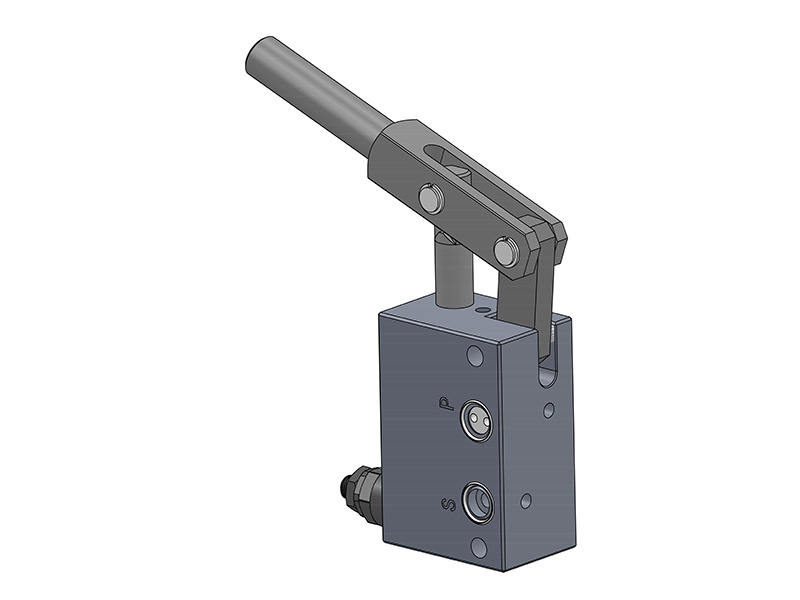

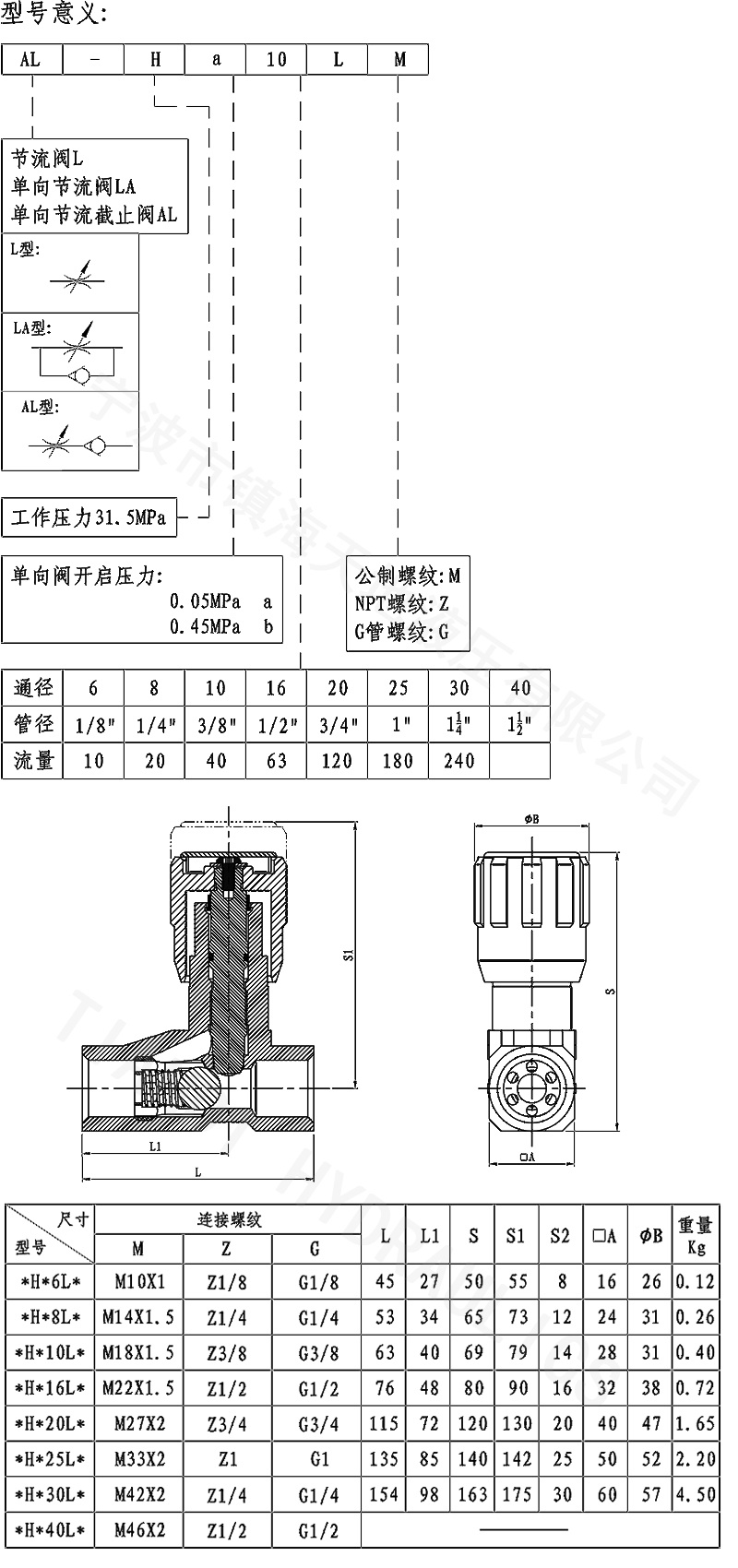

Flow Control Valve

Product details

A flow control valve is an essential element in fluid systems, whether they are hydraulic or pneumatic. The primary function of a flow control valve is to regulate the rate of fluid flow through a pipe or a passage.

In a hydraulic system, the flow control valve can be used to adjust the speed at which a hydraulic actuator, such as a cylinder or a motor, operates. By controlling the flow of hydraulic fluid, it is possible to precisely control the movement speed of the actuator. For example, in a construction equipment like a hydraulic excavator, flow control valves are used to control the speed at which the bucket is raised or lowered.

There are different types of flow control valves. One common type is the throttle valve. The throttle valve works by restricting the cross - sectional area through which the fluid can flow. As the area is reduced, the flow rate of the fluid decreases. Another type is the needle valve, which uses a fine - threaded needle - like component to adjust the flow. The needle can be screwed in or out to change the opening size and thus the flow rate.

Flow control valves can also be non - adjustable or adjustable. Non - adjustable flow control valves are set to a specific flow rate during manufacturing and are used in applications where a constant flow rate is required. Adjustable flow control valves, on the other hand, can be modified during operation to meet different flow requirements. They are often equipped with a handle or a screw mechanism for easy adjustment.

The proper selection and use of flow control valves are crucial for the efficient operation of fluid systems. Incorrectly sized or malfunctioning flow control valves can lead to problems such as inefficient operation, excessive energy consumption, or even damage to the system components. Therefore, when designing a fluid system, careful consideration must be given to the flow control valve requirements.

If you have any questions, please Contact us!

We look forward to working with you to create a good cooperative relationship!