PRODUCT CENTER

We not only enjoy high reputation in the domestic market, but also open the door of overseas market since 2008 when we set up the Foreign Trade Department. Products have been exported to Asia, North America, South America, Australia, New Zealand and other countries and regions.

Product Categories

Categories:

Sandvich Valves

Product details

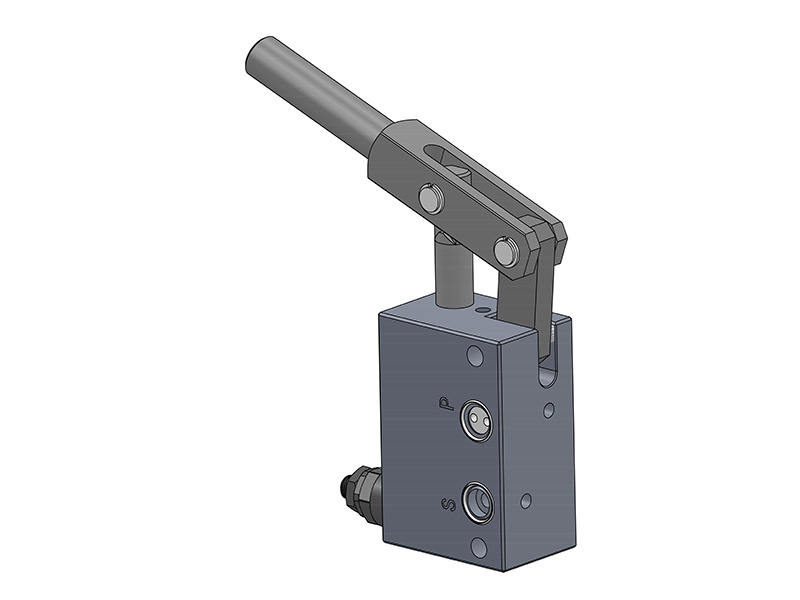

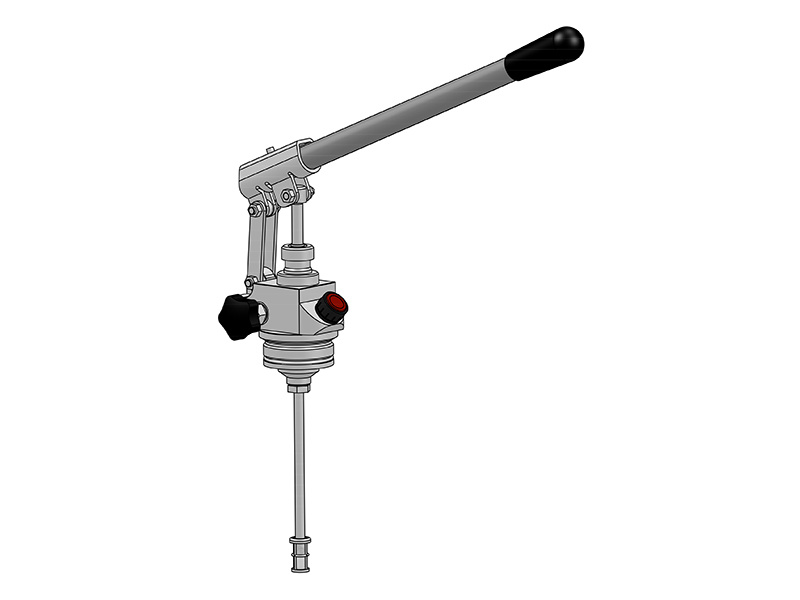

Solenoid directional valve is a vital component in fluid power systems, especially in hydraulic and pneumatic systems. It is used to control the direction of fluid flow.

The solenoid directional valve consists of a valve body and a solenoid. The valve body contains the internal passages and ports through which the fluid flows. The solenoid is an electromechanical device that consists of a coil of wire and a movable plunger or spool. When an electric current is passed through the coil of the solenoid, it generates a magnetic field. This magnetic field causes the plunger or spool to move.

The movement of the plunger or spool within the valve body changes the connection between the different ports, thereby changing the direction of the fluid flow. For example, in a hydraulic system, it can direct the flow of hydraulic fluid to either extend or retract a hydraulic cylinder. In a pneumatic system, it can control the flow of compressed air to different pneumatic actuators.

Solenoid directional valves are available in different types, such as two-position, three-position, and multi-position valves. A two-position valve has two possible flow states, for example, it can either allow the fluid to flow in one direction or block the flow completely. A three-position valve has three possible states, which can be used to achieve more complex flow control, such as allowing the fluid to flow in two different directions or to a neutral position where the fluid is blocked from flowing in either direction.

These valves are often used in automation and control systems. They can be controlled electronically, which makes them suitable for use in applications where remote control or automated operation is required. For example, in an automated manufacturing plant, solenoid directional valves can be controlled by a programmable logic controller (PLC) to operate various hydraulic or pneumatic actuators in a precise and coordinated manner. However, proper sizing and selection of solenoid directional valves are important. Factors such as the flow rate, pressure requirements, and the type of fluid being used need to be considered to ensure the correct performance of the valve in the system.

If you have any questions, please Contact us!

We look forward to working with you to create a good cooperative relationship!